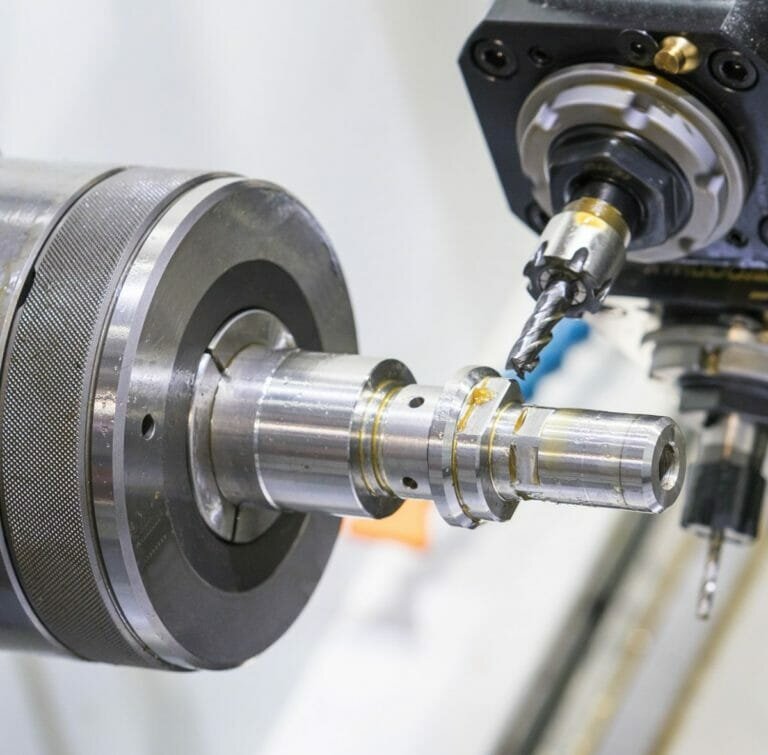

Any subcontract engineering company needs to keep close control over their tooling, ensuring the right tools are always available in order to complete jobs on time and ultimately keep their machines running and customers satisfied.

PSL Datatrack production control software incorporates two modules for definition and management of tooling; Tool Definitions and Bill Of Tools (BOT).

Tool Definitions defines a library of tooling available, records where it is sourced, when it was received and how many are in stock. The module can interface with tool cabinet systems to provide physical control over tool dispensing whilst maintaining an accurate stock count.

Minimum quantities can be set to ensure that any tool shortages are reported and replenished before any knock-on effects to production occur. PSL Datatrack can be configured to filter out old purchases and Goods Received Notes (GRNs) and integration with the Purchase Orders module dramatically reduces the time taken for purchasing tools.

BOT helps manage the tools required for production of a specific component when made on specific machines. The module is controlled by the drawing/issue number and is not quotation or process layout specific, enabling quotations for the same component in different batch sizes to use the same tooling list.

Tool setup sheets can be generated and issued with the job pack for the shop floor. These are variable based on the resource/machine being used and improves utilisation of these machine tools. In other words, if a works order is moved from a planned to an alternative cost centre the relevant tool list can be automatically produced.

In light of Brexit, it is no secret that there has never been a more important time to manage your material stocks and call off material purchase orders but the importance of also having tooling defined and readily available should not be overlooked – this is just as crucial for completing jobs correctly and on-time. Visit www.psldatatrack.com/functionality/planning to find out more about our tooling and other planning modules!