Clear plastic thermoformed tray bases are increasingly commonly used in the packaging of a wide variety of products. However, they pose a challenge for the high-speed automated packaging leading Contrinex to develop a unique family. of sensors.

Contrinex’s small C23PA transparent-object sensors with their patented UV technology easily detect each set of transparent trays after it is formed, initiating a subsequent operation and triggering a counter. The Ecolab certification of these sensors makes them ideally suited for the packaging of food and medical products.

CUSTOMER APPLICATION

Clear plastic thermoformed blister-packs which in this application are used to hold pharmaceutical and surgical products typically comprise a recessed, semi-rigid tray base, vacuum-formed in-line from clear thermoplastic material and sealed with a metal or plastic film after the desired products are loaded.

Typically, blister-packaging lines for surgical products operate in sterile conditions where minimal manual intervention is permitted, to minimise the risk of contamination. If defective bases are identified and rejected after forming, the flow of tray bases to the loading station is not continuous. In this event, a sensor system must inhibit the loading cycle until a base is in position.

Therefore, a sensor is required to detect the presence of transparent tray bases swiftly and reliably, enabling the loading cycle to proceed with minimal delay as soon as a tray is present at the loading station. Standard photoelectric sensors, which use visible red-light sources, proved to be unreliable as they are unable to differentiate reliably between ‘tray present’ and ‘tray not present’ conditions.

An alternative sensor was sought that could reliably detect the presence of a transparent plastic target.

CUSTOMER SOLUTION

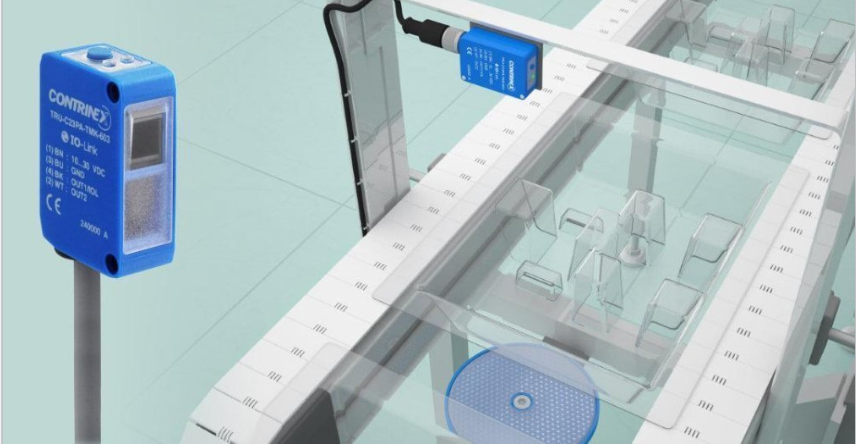

The unique use of an ultraviolet light source in Contrinex’s C23PA UV transparent-object detection sensors is ideal for this application. Members of the miniature cubic C23PA sensor family, these 20mm x 30mm x 10mm sensors are mounted above the machine’s conveyors to detect the presence of transparent tray bases as they arrive at the loading station. Positioning sensors is simple thanks to a range of adjustable mounting brackets, and their auto-collimated optics ensure there are no blind zones.

The transparent-object sensors use a patented reflex operating principle with polarised ultraviolet light with a 275 nm wavelength. This wavelength is chosen because it is where the absorption of the polarized UV light by a range of commonly used plastics is maximised. A choice of size and shape of the custom-designed UV reflectors which use high-tech plastic materials with excellent reflective properties, simplifies installation.

The customer makes use of both of the PNP normally-open output and IO-Link, the standardised point-to-point serial connection protocol for sensors and actuators, which is included within the sensors for no additional cost.

An additional option across the C23PA family of photoelectric sensors is to have a second switched output to provide a ‘stability alarm’ in the event of reduced sensitivity, flagging the need for preventative maintenance before any performance degradation occurs. This provides extra functionality which is simple to implement within the machine and at no additional cost for the sensor.

The robust sensors feature Ecolab-certified plastic housings and a sensing range up to 1200 mm, adjustable using a teach button or IO-Link to accommodate a wide range of applications. Sensitivity parameters are stored on the sensor’s inbuilt memory and may be retrieved or updated remotely via IO-Link, eliminating the need for manual adjustment.

The C23PA family of sensors also benefits from having a range of complementary low-cost stainless-steel mounting and protection bracketry options.

PRODUCT ADVANTAGES

🕵🏽 Exceptional reliable detection of clear objects

✨ Reliable detection of the thinnest transparent materials

👓 Very low sensitivity to dust, liquid droplets and splashes

🔧 Preventative Maintenance alarm trigger

📏 Long sensing ranges

💪 Robust & reliable

👩🏫 Simple one- or two-step teach procedure

🎛️ IO-Link Ideal for Industry 4

Customer benefits:

- UV sensors ensure reliable detection of transparent targets

- Safe detection of the thinnest transparent materials

- Maximum operating reserve owing to high absorption factor of UV light by transparent plastics

- Elimination of multiple switching on a single target

- Reliable operation without the need for manual intervention

- Very low sensitivity to dust, liquid droplets and splashes

- Wide operating range accommodates a full range of tray sizes

- Simple one- or two-step teach procedure optimises initial sensor set-up

- Sensitivity parameters are retrieved or updated remotely via IO-Link

- Stability alarm highlights reduced sensitivity, avoiding unplanned stoppages

Product advantages:

- Ultraviolet reflex photoelectric sensors for transparent object detection

- Very low sensitivity to target shape

- Pre-taught sensitivity parameters stored on inbuilt sensor memory

- Highly tolerant of contamination by dust, liquid droplets or splashes

- IO-Link connectivity available at no extra cost on PNP versions

- Robust, Ecolab approved miniature sensors

Read more at www.UV.PLUSAx.co.uk or Click to download Contrinex’s Product Overview brochure to find out more.

The C23 sensor family is available with five sensing technologies; industry-standard PNP or NPN, 3‑wire or 4-wire outputs; a choice of PVC-sheathed cable or an integrated M8 connector; and a wide choice of low-cost mounting and protection brackets.