Alloyed recently returned from what was universally accepted to be a busy and productive Formnext event in Frankfurt, and was pleased to have its additively manufactured copper cooling plate (exhibited on its booth) highlighted in the Cool Parts Show video series from Additive Manufacturing Media, Cincinnati, USA

Michael Holmes, MD at Alloyed comments, “Formnext 2021 was the first large-scale event that we have exhibited at since the merger of Betatype and Oxmet Technologies at the end of 2019. The merger means that Alloyed offers a unique and complementary stack of technologies for the manufacture of advanced metal components by additive manufacturing (AM) and traditional means. The company has developed and uses a proprietary computational platform and advanced materials modelling to identify the right alloy composition for any application and process. This, coupled with Alloyed’s Engine technology specifically for AM with the capability to deliver better functioning parts faster and more cost-effectively for a wide range of applications set Alloyed apart at Formnext. The company’s turnkey solution provides technology at every scale from alloy composition, material engineering and part design through to scale for mass production. The cooling plate is a great example of what can be done when optimised AM geometry is combined with optimised AM material properties.”

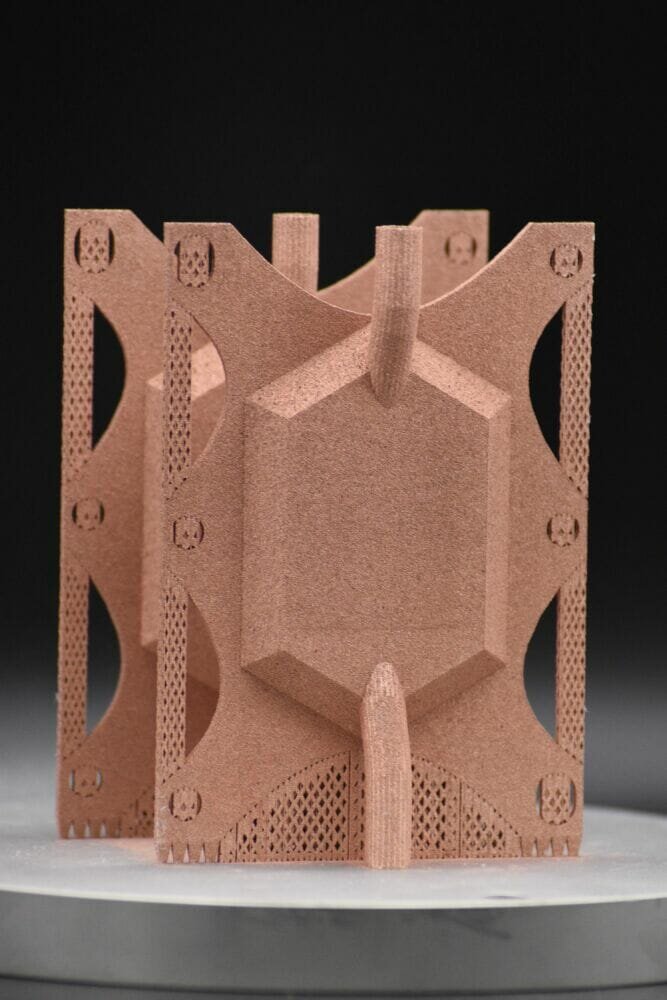

The copper cooling plate is specifically designed for use in datacentres, and as a liquid cooling system, can have a significant impact on reducing energy usage compared to conventional air cooling methods. AM is the ideal technology to make cooling plates as more complex geometries can be produced less expensively and with greater functionality and performance — both in terms of heat exchanged and liquid pressure dropped. The unibody nature of the additive part results in a simpler and more efficient component which outperforms traditionally assembled cold plates. Due to reduced assembly needs, the parts are also easier to install and have lower maintenance requirements.

However, copper is a notoriously difficult metal to process using AM due to high thermal conductivity of the fused part (the very reason that it is and ideal material for cooling plates) and its high natural reflectivity.

JX Nippon Mining & Metals (JXNMM) and Alloyed have partnered to offer a comprehensive portfolio of laser bed fusion solutions for copper and its alloys. JXNMM has developed copper powders with improved printability, allowing the production of parts with very low porosity and electrical conductivity. This is achieved through a novel surface treatment which adds an anti-oxidation effect and prevents an increase in oxygen content. For electron beam processes, the surface treatment inhibits powder sintering (thus increasing design flexibility) and the surface treatment can also be used to increase absorptivity in laser beam systems. The powder can achieve relative densities of >99.95% using the electron beam process and 99.91% using the laser bed process.

Enrique Alabort, Co-Founder of Alloyed and Head of Alloyed Japan says, “The success of the copper cooling plate that was on show at Formnext is due to the combined expertise of Alloyed and JXNMM. The materials developed by JX allow Alloyed to use its proprietary Engine® and Architect® software to produce the high-fidelity complex geometries and lattice structures in the cooling plate. Alloyed specialises in the production of fine-featured components and can produce thin walls down to a mean thickness of 190 microns, and its expertise in design for AM allows it to extract the most value from the design freedom enabled by the process. This expertise is vividly shown in the design and production of the copper liquid cooling plate.”

Alloyed provides a compelling offering for optimising advanced digital metal manufacturing applications, and is committed to making its customers high-performance components and processes even better. Joining the Alloys-By-Design (ABD®) brand with Betatype and a facility that makes parts — Alloyed Digital Manufacture (ADM) — and partnering with expert material developers such as JX means Alloyed can offer clients the development of superior and customised alloys, unprecedented levels of advanced process control and performance, and expert metal AM production capabilities from application development through to production. In this way, Alloyed provides customers with a palette of complementary expertise and services that optimise the production of metal parts through digital manufacturing.