Quality assurance (QA) is an essential step of every manufacturing process — by ensuring parts are made to specifications, manufacturers can avoid the notorious costs associated with defective products. However, inspecting highly reflective moving parts has historically been challenging for traditional machine vision solutions, meaning automated QA was not an option, the Ispekto S70 overcomes these issues.

The process of visual quality inspection can generally be divided into three consecutive steps — image acquisition, which refers to the process of acquiring a high-quality image of the item to be inspected; part recognition, where the inspection system recognises that the acquired image contains the part to inspect; and finally part inspection, which is the analysis done to establish whether the part is good or defected.

Unfortunately, when parts made of highly reflective material are moving, for example on a conveyor belt, the image acquisition step becomes particularly challenging for machine vision systems.

The challenge—reflective and moving

In numerous manufacturing facilities, the parts and modules produced are made of materials that are highly reflective, such as metals or plastics. Examples include metallic parts just out of the forging or machining process, coated printed circuit boards (PCBs) on electronics manufacturing lines, or metallic elements assembled in mechanical assembly lines.

Reflective objects create a challenge for visual quality inspection since light reflected towards the camera often causes image saturation and loss of details. High dynamic range (HDR) is a common methodology used to reduce reflections in an image. This is a technique used to reproduce a greater dynamic range of luminosity than is traditionally possible with standard digital imaging or photographic techniques.

However, a significantly bigger challenge is when the light source is an embedded lighting module, which is part of the inspection system, with an illumination path that is parallel to the camera’s line of sight (LOS). In these cases, the likelihood of back reflection and its intensity increases.

HDR is far from adequate in this scenario, and state-of-the-art proprietary anti-reflection (AR) techniques need to be applied. These techniques require the generation of multiple images using different directional lighting modules. These images are then fused together to create a single, reflection-free image. Due to the inherently complex nature of this process, most existing AR techniques do not perform robustly enough for actual deployment on a production floor.

The challenge is compounded when the parts are in motion. In many cases, highly reflective parts are moving through the required inspection station and cannot be stopped to enable stationary inspection. Until recently, it was considered impossible to fuse together multiple images where the part has a different location and spatial orientation in each image. However, a solution is now available.

The solution — a technological breakthrough

Inspekto has solved this problem by leveraging several new developments to create a unique, patent-pending AR technology.

The first is its Autonomous Machine Vision AI (AMV-AI™) technology, containing three AI-based engines working in tandem. The first of the three engines is the Acquisition AI engine, a unique AI technology created to dynamically adapt the parameters of an electro-optics system to a specific use-case, in real time. The second engine recognises the part to be inspected, while the third determines whether it is good or defected by comparing it to the characteristics of a perfect part, memorised during the initial set up process.

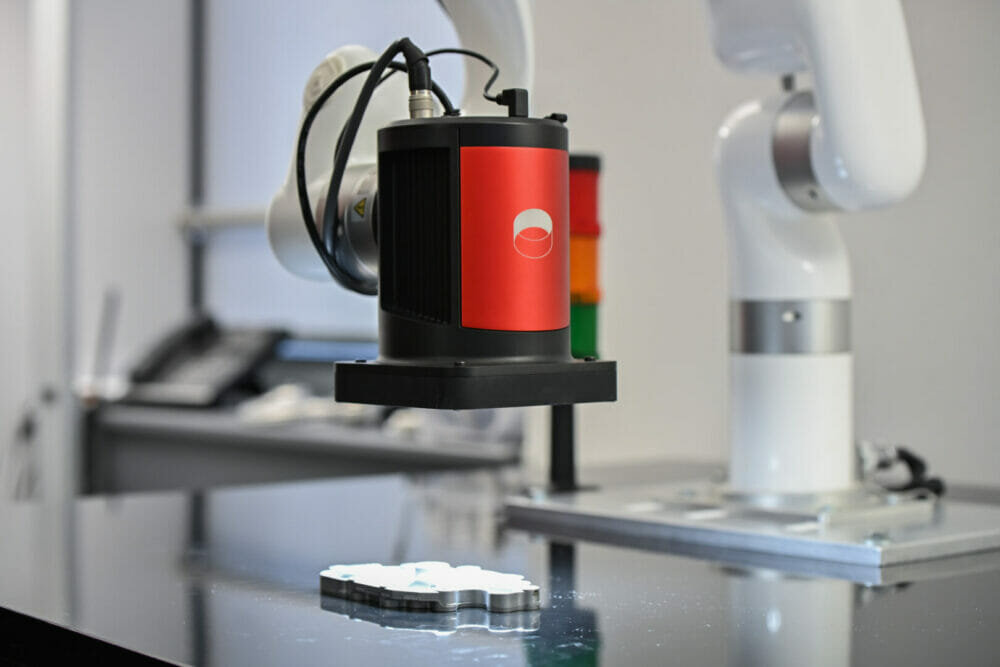

The second is its ultra-flexible electro-optics system, the INSPEKTO S70, which provides a large playing field for the Acquisition AI engine to tailor the inspection profile to the requirements of each case study. The INSPEKTO S70 offers a wide variety of parameters that can be autonomously adjusted by the system’s AI, so that adjustments are specific to the product being inspected, ensuring extreme accuracy of inspection. Real-time, dynamic adjustments are performed autonomously to the full set of electro-optics parameters.

Inspekto’s AR technology is unique in several aspects. Firstly, in line with our objective to create solutions that are easy and user-friendly to deploy, our AR technology creates no flickering that might disturb or inconvenience employees working near the INSPEKTO S70.

Secondly, by combining unique AR and HDR into an integrated technology, reflection from both external light sources and the INSPEKTO S70’s integrated illumination system is dramatically reduced.

Finally, the system’s robust Recognition AI engine, designed to ensure that the part to inspect is actually present in the image, enables the fusing of multiple images together, even when the part is in a different location or orientation compared to the memorised standards.

In this way, Inspekto’s AR technology can enable the accurate inspection of highly reflective, moving parts without the traditional constraints associated with this process. This makes the INSPEKTO S70 the only industrial visual inspection solution able to perform in these scenarios, opening the doors of automated QA to a wide variety of industrial process in industries as diverse as electronics, metalworking, plastic injection moulding and more.

For more information on Inspekto’s unique AR technology, and for a free demo of the INSPEKTO S70 for your industrial parts, visit www.optimaxonline.com.