Smart highlights and sustainable mobility

Also this year the EMO is a must-attend event for companies from the metalworking sector. From 16 to 21 September 2023 CERATIZIT will showcase its new products and innovations in hall 5 at stand C69, invite to interesting technical discussions and set trends in the industry – not least in terms of sustainability.

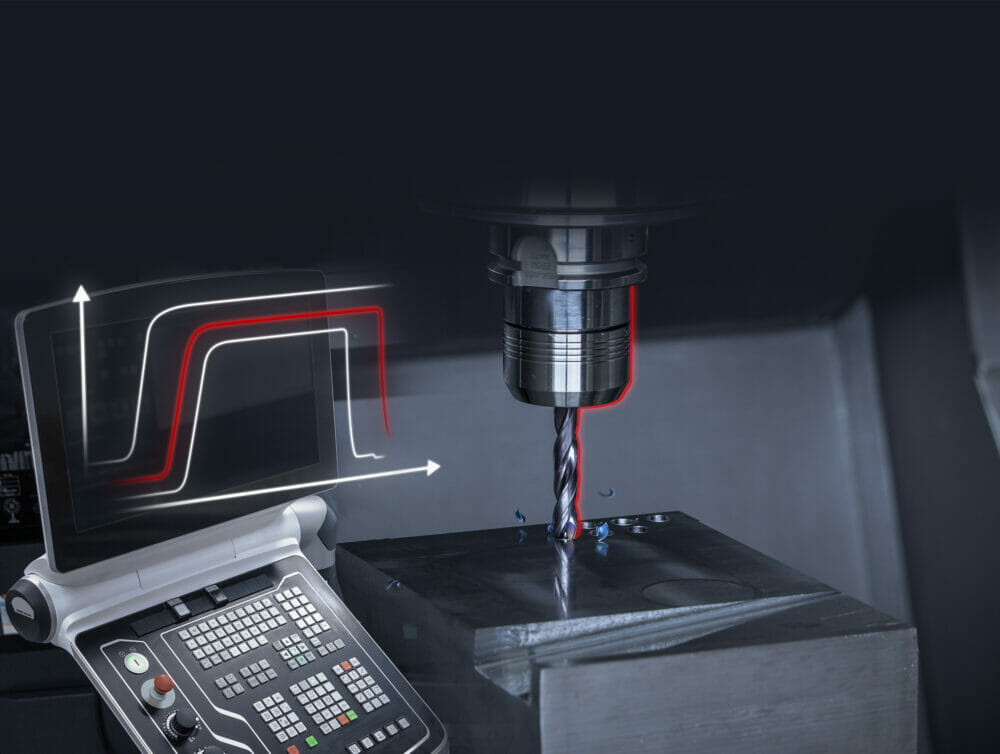

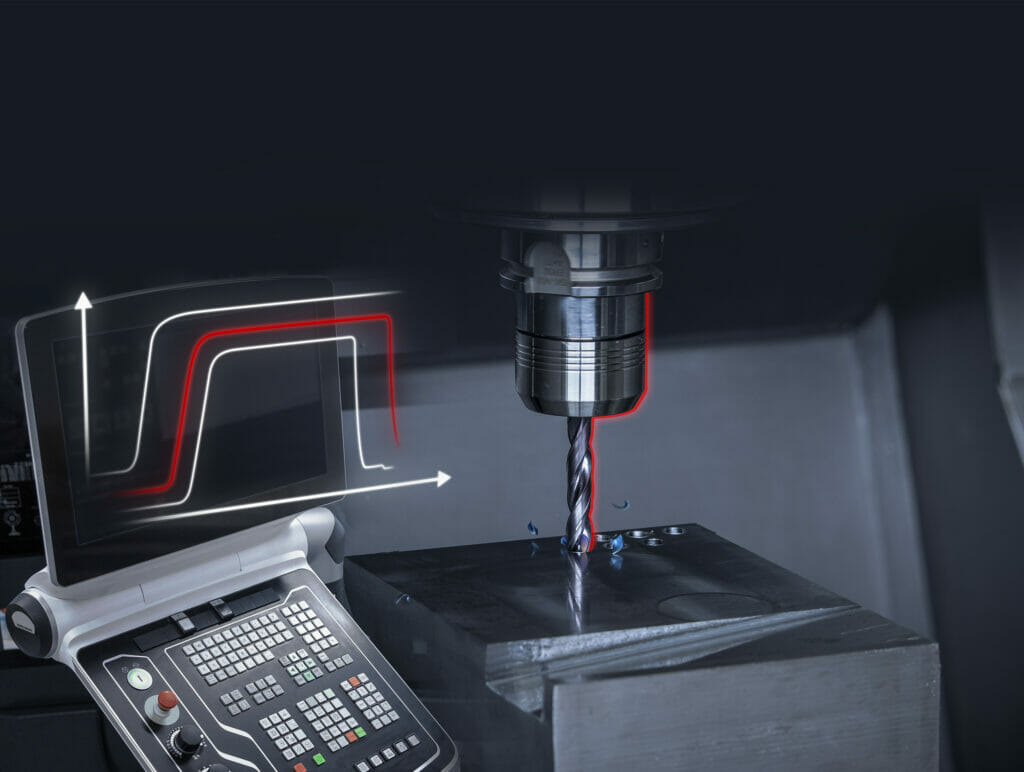

The future of production is smart, that much is certain. But the ways to the “Smart Factory” are manifold. CERATIZIT has been at the cutting edge of the digital machining future for many years, for example with the monitoring and control system CERAsmart ToolScope. This system permanently records the signals from the cutting machine during the production process, visualises them and provides important information for process control, machine protection and documentation.

“If they flow into the right systems, this kind of data can be extremely valuable for the machinist. But only if they are evaluated, processed and made available to the user in this way do they also offer him the corresponding added value. We already meet this challenge very successfully with our CERAsmart Cockpit. However, there is no question of resting on our laurels: rather, we want to continue to broaden the paths in terms of digitalisation and the real smart factory,” emphasises Andreas Kordwig, Director Global Product Management at CERATIZIT.

Sophisticated automation solutions are further building blocks for the Smart Factory. With the workpiece automation R-C2 CERATIZIT shows the link between pallet automation and robot direct loading. Because with the R-C2 module the workpieces are gripped directly with the vice, which also functions as a clamping device. This makes a separate gripper superfluous, avoids possible damage and saves the user additional set-up work.

FreeTurn programming – made simple

What until a few years ago was the wishful thinking of every turning expert – a universal tool for roughing, finishing, contour turning, face turning and longitudinal turning – has long since boosted efficiency in production halls: With the revolutionary High Dynamic Turning process and the specially developed FreeTurn tools, turning technology has entered a new dimension. “The next stage of development has now also been given to the programming of the HDT process. Faster and easier to the efficient process? An offer that no one can refuse – our ToolPath as well as some other smart solutions make it possible”, reveals Dr. Uwe Schleinkofer, Director R&D at CERATIZIT.

PCF for transparency in the CO2 footprint

In order for sustainability not only to remain as an abstract construct in people’s minds, transparency must be created above all. A signpost in this context is the so-called Product Carbon Footprint (PCF), which indicates the amount of greenhouse gases emitted during the production of the product. For this purpose, CERATIZIT was the first company in the industry to present a model for calculating and classifying the PCF of its carbide products. This classification model is similar to the energy consumption labelling on electrical appliances. In future, buyers will be able to see a product’s PCF at a glance and make an informed decision based on this data: For example, to choose products with a low carbon footprint – like the carbide grade of the upGRADE range from CERATIZIT.

Mobility from the sunny side

How will we get around in the future? A question with many answers – CERATIZIT helps to solve some of them with adapted tooling solutions for the automotive industry. However, research and development is also being carried out outside the major manufacturers to find out which concepts can be used to make locomotion sustainable. And it is precisely such “think tanks” that CERATIZIT supports with know-how and tooling power, such as the Green Team of the University of Stuttgart or the project “Sonnenwagen”. The current vehicle, the Covestro Adelie, can be examined at the CERATIZIT stand. The team of students will also be available to answer questions about this extraordinary solar car. They will explain how Covestro Adelie generates electrical energy via the solar cells on its surface, what challenges are still to come in the course of the year and how CERATIZIT was able to support the construction of the latest solar car.

Live demos and tool highlights

No trade fair without interesting live demos on a DMG machine at the stand! “The past trade fairs have shown how popular our live demonstrations are. Among other things, we can present our High Dynamic Turning, but also show one or the other current tooling highlight ‘in action’”, says Steffen Baur, Head of Product Management at CERATIZIT. Furthermore, it is worthwhile to take part in the raffle at the exhibition stand, where many interesting goodies are waiting for their new owners.

The CERATIZIT Group can be found in hall 5, stand C69. Further information under https://cuttingtools.ceratizit.com/