Addmore Engineering Ltd, based in Bedford, is a CNC machining company who supply high-precision parts to the automotive, medical, oil and gas industries. What started from a barn in Watford is now a large operation which spans over 3 buildings, employs 48 skilled machinists and runs 24 hours a day.

Frank Vasquez, an engineer with an expertise in sliding head machines, started the company decades ago. Having bought 2 sliding-head machines, Frank launched Addmore Engineering Ltd and quickly began to build a solid reputation for the high-precision parts he was producing and the complex customer requirements he was able to meet. A family business at heart, his son, Ben Vasquez, joined the company when he was 17 years old and was put to work on the CNC machines. Remaining on the machines for 10 years, Ben gained the same level of expertise that his father was known for. Once Frank stepped down as Managing Director, Ben took over his role and has been running Addmore ever since.

Specialising in highly precise and intricately machined parts, Addmore turned to Ceratizit over 20 years ago to help them with their complex component and tooling needs. Regularly visited by an Applications Sales Engineer and a Technical Sales Engineer from CERATZIT, a strong working relationship has been built over the years, which has had a profoundly positive impact the growth the company has seen over the past 2 decades.

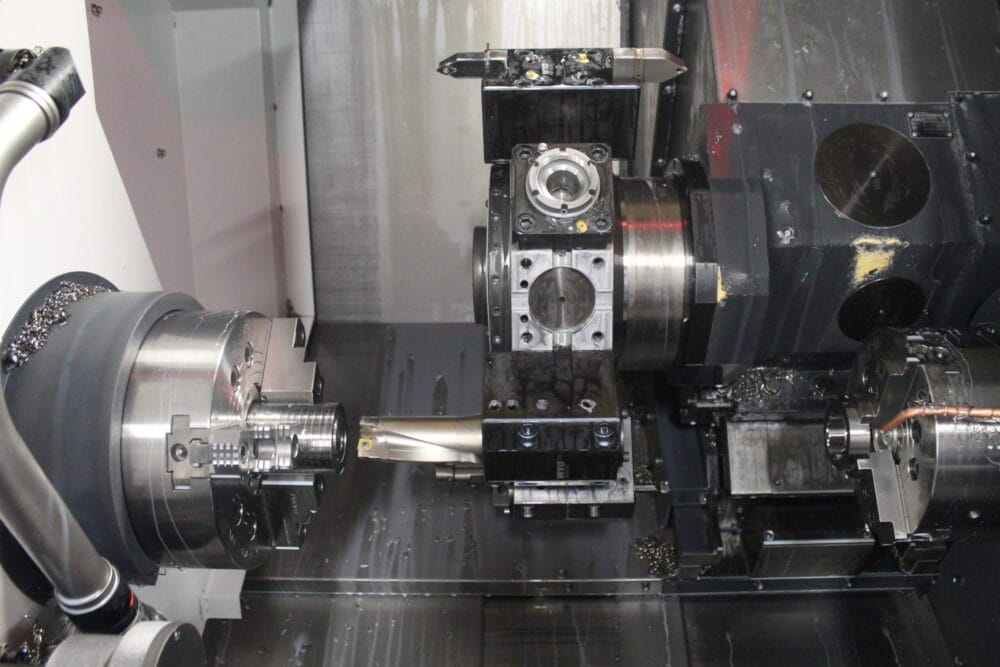

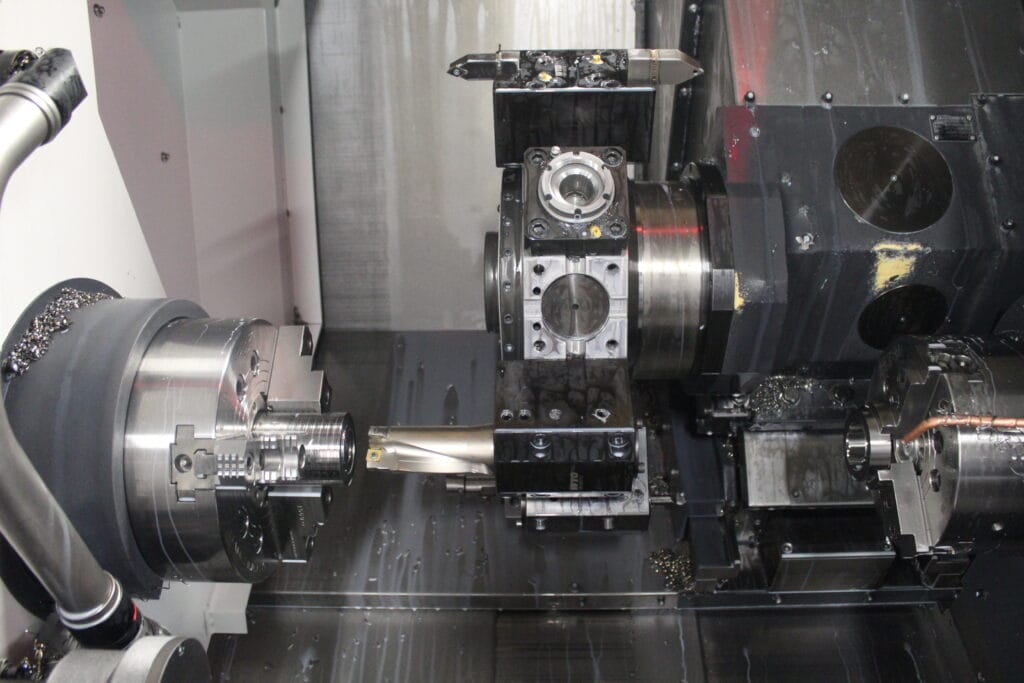

Whilst many of CERATZIT’s inserts have been used by the Bedford based company for such a long time that they have become machining staples, a recent switch made by Addmore was to Ceratizit’s Pentron Drill. The initial swap to the Pentron Drill was made in order to increase tool life and save money on tool-replacement costs. The tool Addmore were using previously was the 2XD 46mm Dia C900 from CERATIZIT. Although this tool was successfully completing the job, the inserts were getting pickup and sticking to chips. After adjusting the cutting data to try and solve these problems, CERATIZIT suggested that Addmore try a Pentron drill on this machine, and a trial was book for the following week.

Above: SOGX insert with 03 geometry and BK8430 coating with optimised flutes

Immediate benefits were seen from using CERATIZIT’s 2XD 46mm KUB Pentron drill. Whereas the previous drill had an insert life of between 55-75 parts per edge, the Pentron drill increased this to 120+ parts per edge, making an improvement of well over 50%. Shaun Thornton, Technical Manager for Ceratizit UK, explains that ‘this improvement is down to CERATIZIT’s SOGX 03 geometry and BK8430 coating in combination with the Pentron Drill. This specialist coating minimises chip-sticking and increases swarf evacuation due to its optimised flutes.’ As well as the cost-saving benefits which come from the extended insert life of the Pentron drill, switching to this insert also meant that machine cycle time was reduced by 10%, allowing for more parts to be machined per day.

Warren Howard, Technical Sales Engineer for CERATIZIT UK, commented how ‘CERATIZIT is always developing and improving upon our cutting tool technology, and it’s important for our Technical Sales Engineers and Application Sales Engineers to recognise areas where improvements can be made in our customers’ machining processes. We recommended the Pentron drill, knowing that the significantly increased tool life of this insert would mean that we sold fewer inserts to the company. We want our customers to know that they can put their trust in us and will have faith in our machining solutions going forward.’

Like many other companies who rely on CERATIZIT’s reliable, durable and high-quality parts, Addmore have CERATIZIT vending machines on-site which allows them to access new tools as and when they are needed. Enabling 24-hour access to tooling and parts on hand to prevent machine stop-time aren’t the only benefits that were highlighted by Ben, as he also remarked how useful it is to be able to see the company’s tooling costs for specific parts and machines.

Ben was also keen to highlight how CERATIZIT go over and above simply selling tools and providing a catalogue of products. The constant line of communication and 24/7 access to technical support is just as valued as the high-quality tooling for Addmore. ‘I don’t want to look through a brochure and guess what the best solution would be’, explained Ben, ‘I want to talk to someone who understands what I need and who recommend to me, then and there, the right tool for the job. This is where Drew and Warren have been outstanding; I know I can pick up the phone and speak to them if I have any problems. If these problems require tooling to solve them, then these are delivered the next day as well’.

Warren and Drew regularly visit Addmore to ensure that everything is running smoothly. Having carried out these visits for many years, they have allowed CERATIZIT to become acquainted with Addmore as a company, and to understand their specific machining needs and processes. Drew commented how ‘working with Addmore for such a long time had meant that I have really gotten to know the company. When I make recommendations now, I know that I will be recommending the very best thing for the company, and they trust me enough to know that I will only ever endorse machining parts that will well work for them.’ Warren added, ‘the long-standing professional relationship we have with Addmore is a testament to how well we work together. Having already supported them for more than 20 years, we’re sure that our relationship will continue for the next 20 years, and beyond!’

Above: 2XD 46mm KUB Pentron drill from CERATIZIT

As a company which is always growing, the future looks bright for Addmore Engineering Ltd. With 42 CNC machines, many of which are running 24 hours a day, the company continues to carry out the work which started decades ago by Frank Vasques. Honouring his legacy, and even though Addmore is now a significantly larger operation than what started with 2 machines in an old barn, it is clear to see that a passion for precision still goes into every part that is machined.