Any contamination is a food safety issue that can have a negative and potentially irreparable effect on a pet processors reputation. Catching metal contaminants at the tail-end of lines can be more expensive. Fortress Technology reveals the benefits of installing its inline metal detection equipment upstream on pet processing lines.

BREEDING TRUST

Providing a plethora of well-being benefits to owners, from companionship to support therapy and even preventing certain health conditions, pets undoubtedly play a vital role in their humans’ lives. Currently, more than half of UK households (57% in 2023) own at least one pet[1], with a large majority considering them part of the family[2].

Most owners will say the love of a pet is priceless. Their bank accounts, however, disagree. Sales of natural versions of pet slurries, kibble and raw diets has escalated, with many owners admitting their furry friends eat better than they do. Testament to this, 21% of British householders admit to spending the same amount on pet food, if not more, than they do on their own groceries.[3]

According to the association UK Pet Food, over 50 pieces of legislation govern the manufacturing of pet food in the UK to ensure consistent high standards and utmost safety and hygiene. The Guide to Good Practice for the Manufacture of Safe Pet Food developed by FEDIAF comprehensively covers the safety and hygiene of pet food processes and products.

Like human food, pet food processors are required to adopt a HACCP and formal foreign bodies control policy. This includes introducing measures to prevent, control or detect potential contaminants identified by hazard assessments. Sensitive and hygienic inline contaminant detection equipment can play a crucial role in assisting pet food processors to protect pets, safeguard their brand and adhere to these stringent regulations.

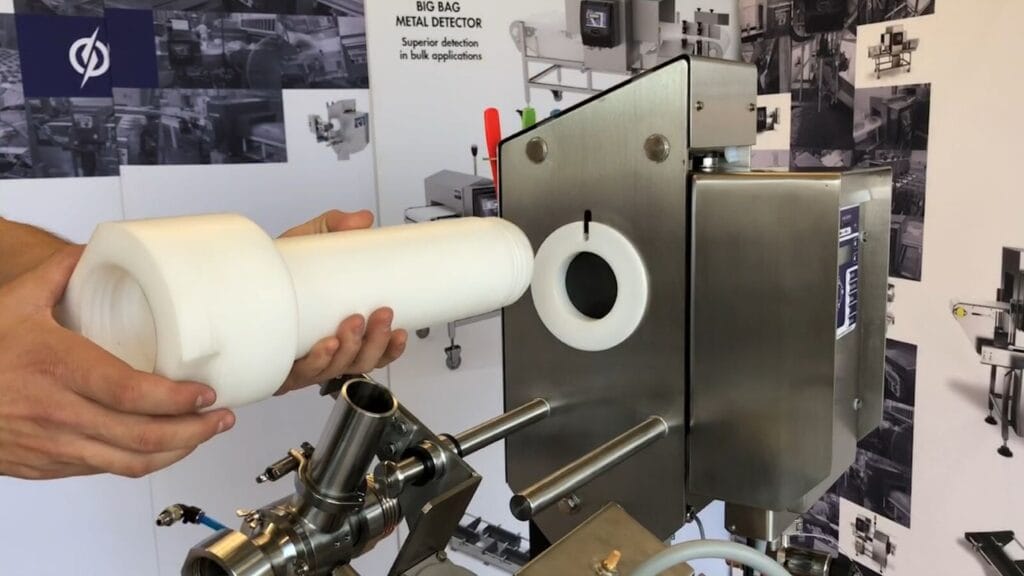

A single piece of ultra-hygienic removable Delrin tube on the Meat Pump eliminates crevices that may harbour bacteria.

PROTECTING BRANDS

With wet viscous pet food processing compliance demanding the highest levels of sanitation, the Fortress Meat Pump Metal Detector tackles contamination and hygiene simultaneously. Utilised to prevent metal contaminants reaching the cooking and packing stages, the inspection system’s removable plastic tube is constructed from ultra-hygienic food-safe Delrin.

IP69K-rated, the slimline machine is constructed with no metal ends, ensuring no bacteria-harbouring crevices. Customised Delrin wrenches stored on the machine enable operators on wet food processing lines to loosen and tighten the pipe’s threads without the risk of damaging the equipment. An easy roll out mobile frame gives processors maximum flexibility. Additionally, the unique rail mounted reject valve supports fast removal of the pipe for cleaning and reassembly.

In less than three minutes, operatives can blast high pressure water jets through the system, eliminating bacteria and product residue to prevent cross contamination. Features like this are especially useful in enclosed metal detector pipeline configurations, which are virtually impossible to access efficiently. By optimising hygiene standards, the Fortress Meat Pump machine helps to prevent cross-contact contamination and the spread of bacteria in pet food products. Providing quality assurance to both pet owners and processors alike.

There are virtually no limitations to installing Metal Detectors, although specific features of likely contaminants, the product, packaging, processing and supply chain may determine whether metal detection is chosen for a particular point on a pet food processing line. Should pet food processors need to detect other physical contaminants, for example glass or bone, they may opt for a Pipeline X-Ray machine.

Gravity Metal Detectors are the best option for “free-falling” dry kibble and pet treat applications. These are often located between product chutes and hoppers on pet food mixing lines and integrated with automated packing systems and checkweighers.

For final quality checks, highly sensitive Bulk Metal Detectors, Checkweighers and Combination systems can be added to inspect large pet food bags and boxed wet food trays.

Over 50 pieces of legislation govern the manufacturing of pet food in the UK.

FETCH THE STICK

To enhance and optimise these inspection systems, automatic testing can be deployed. Running performance and verification tests at regular intervals, these automatic tests are cleaner, accurate, and labour and waste saving.

A number of Fortress pet processors use Halo automatic testing to reduce the risk of human error by eliminating the challenge of manually inserting and retrieving test sticks and balls from a closed pipeline or gravity pet food inspection systems.

Test sticks involve the operators inserting the test piece in the gap between the tube and the aperture, which is the most sensitive part of the metal detector. Whilst this may deliver a great signal, it’s not representative of testing for metal contaminants in the product flow.

Equally, introducing the test balls into the actual product flow can be even more convoluted and time-consuming. This process requires operators to recover the test sample from the product after it has flowed through the pipeline system or disassemble and reseal the pipe. Not only is this messy, but it can also increase test times from several minutes to between 15 to 20 minutes.

Testing hard-to-access kibble gravity metal detectors can be even more challenging. Climbing up above production silos to perform testing manually is usually a two-person task and can be a safety risk even with the most robust precautions in place. Additionally, dropping the test sample from a height, consistently through the exact centre of the aperture and product flow is nearly impossible. So, rarely challenges the metal detectors’ capability.

To overcome these gravity access challenges, some metal detectors may be fitted with a test ball insertion port at the top of the non-metallic product tube. Although this might make it easier to insert the test balls, in most cases the freefall height is well above the local insertion port. This means that the test is performed at a slower speed and doesn’t reflect the true freefalling velocity of real-life contaminants falling from height or accurately challenge the reject reaction time.

The Fortress automatic testing solution Halo solves this by enabling pet processors to activate tests remotely, locally or automatically on a timer. Tests can be scheduled without the need to halt production to place and retrieve test samples. The validated test data can then be digitally saved for audit purposes. Using Contact 4.0, pet processors can also network multiple machines to generate more comprehensive machine performance reports.

With British animal owners spending such sizable sums on premium wet and dry foods, pet food processors need to ensure every meal and treat has undergone thorough contamination detection. No matter the ingredients or application format, pet food production lines today must reflect the authentic safety, wellbeing and trust that owners and their faithful companions expect.

[1] https://www.ukpetfood.org/information-centre/statistics/uk-pet-population.html

[2] https://www.petsmag.co.uk/charity-reveals-findings-of-largest-ever-survey-of-uk-pets-and-their-people/

[3] https://www.companionlife.co.uk/almost-one-in-ten-brits-spend-more-on-pet-food-than-household-food/