We have many years of working with suppliers to the automotive industry as well as with the permanent marking of components and parts for traceability and tracking purposes. One such project this year was to design and build a machine to laser mark tamper-proof labels for part identification of components for a client in the automotive racing industry.

In support of critical industries, we engineered a machine for a new client to automate the production of straps for face masks. We are now working on new projects with this client focusing on process automation, increasing productivity, improving standardisation and ensuring consistency.

A second project requirement due to the COVID pandemic was the build of a repeat machine of one produced some 15 years ago for Intersurgical’s plant in Lithuania. Intersurgical is a global designer, manufacturer and supplier of a wide range of high-quality medical devices for respiratory support.

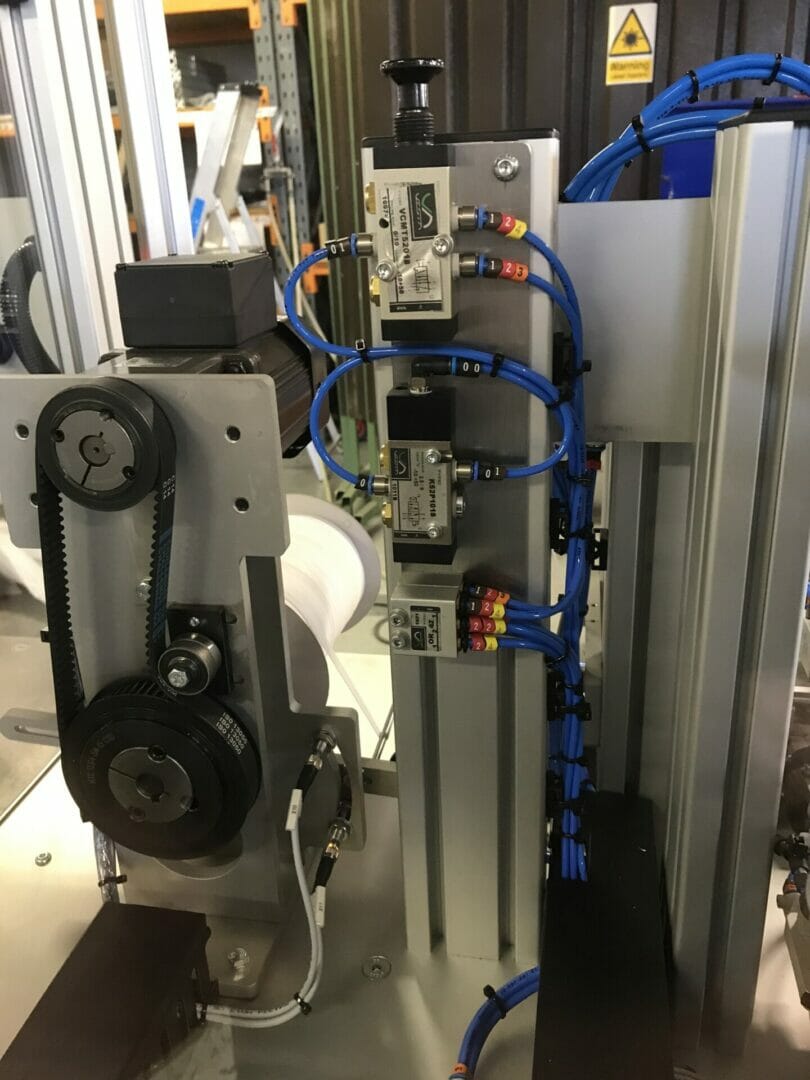

TF Automation revisited the original design and have basically produced the same machine to support the existing one, using the latest technology to laser mark the manufacturer’s logo and product reference on their Hydroguard Mini medical oxygen filters.

We were delighted this year to launch our newly updated website, focusing on the engineering and manufacturing of bespoke special purpose machinery. The revamped site focusses on the company’s capabilities and expertise in a wide range of disciplines from process automation, robotics, laser marking and assembly and testing. An important new area on the site, highlighting TF’s vast experience, is Industries, which identifies the main sectors the company has supplied to for many years, including Automotive, Aerospace, Medical and Industrial.

To find out more or to discuss your next automation project with our design team, contact us on 01274 308005 or info@tfautomation.co.uk or visit our website www.tfautomation.co.uk.